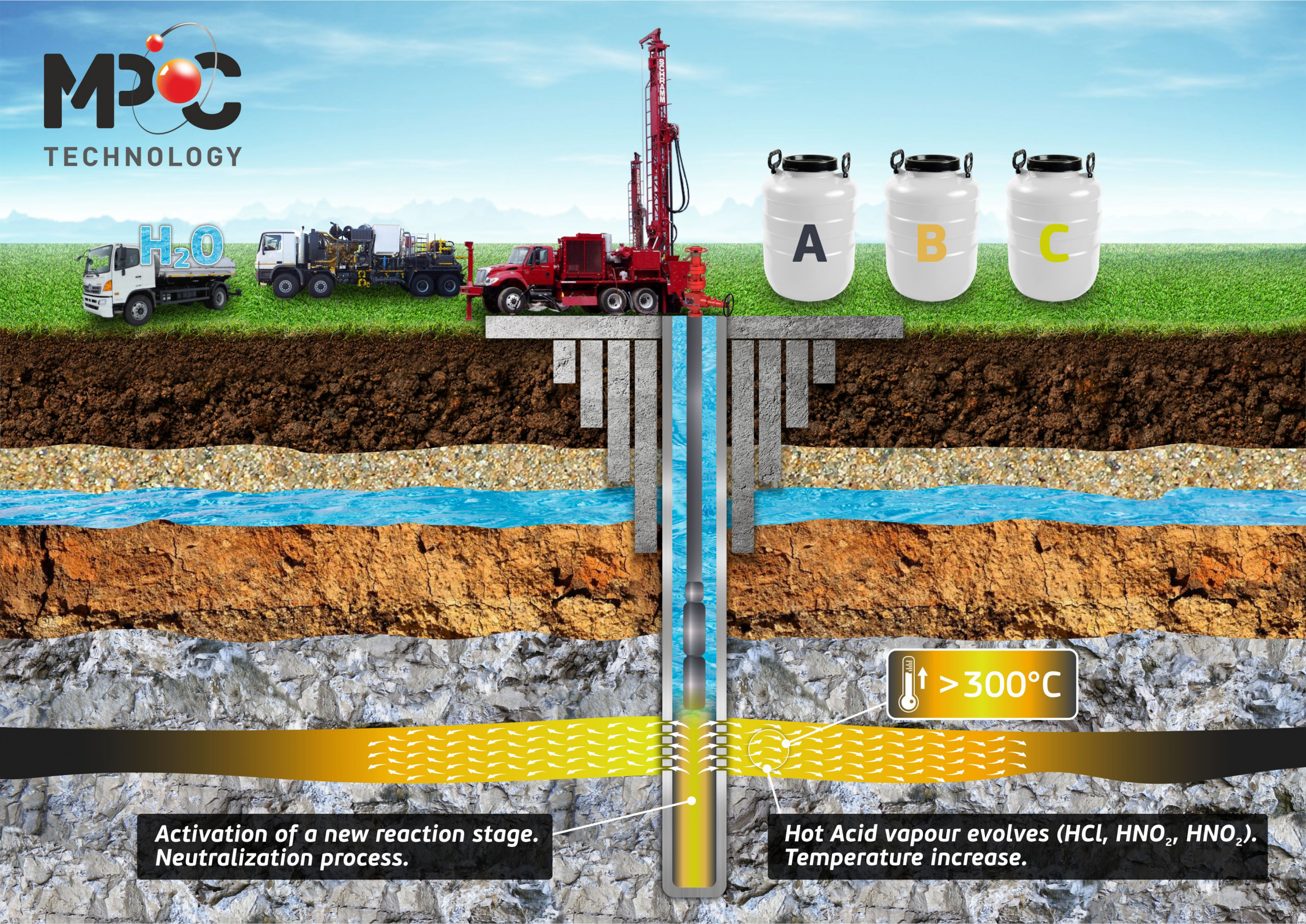

MPC Method

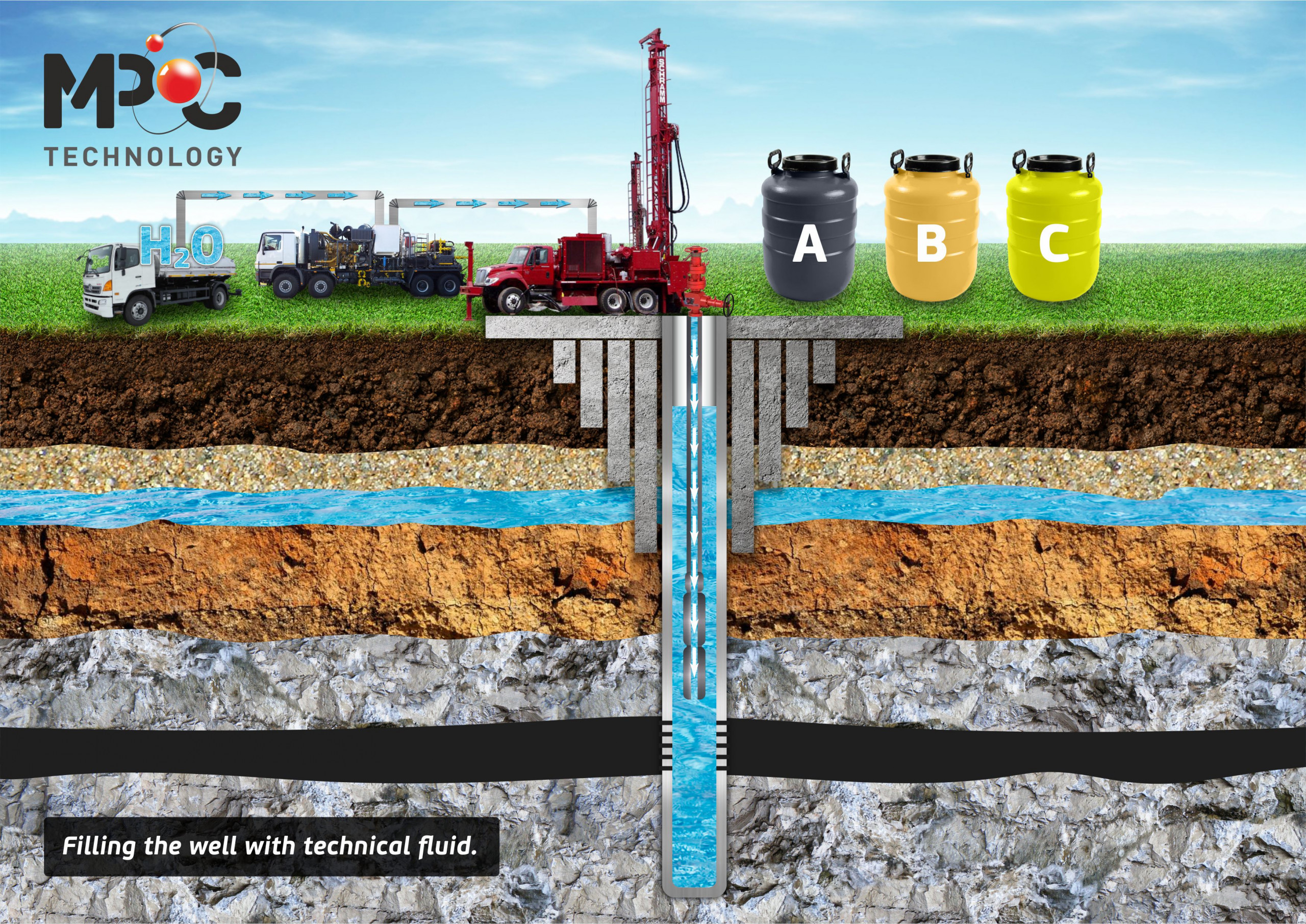

Method is aimed at increasing the output of wells, by active (multistage) physical and chemical action of burning in water high-energy compounds and combustive and oxidizing mixtures of new generation on the zone of uncovered production formation. Our company synthesizes them in laboratory conditions. The created chemical systems can be oxidized in water which is ballast in the well.

The Oxidation-reduction Mixes (ORM), and also products of their reaction are eco-friendly systems (environmental research conclusions are available). All chemical mixes are prepared according to technical specifications and the patent which are the intellectual property of developers of technology.

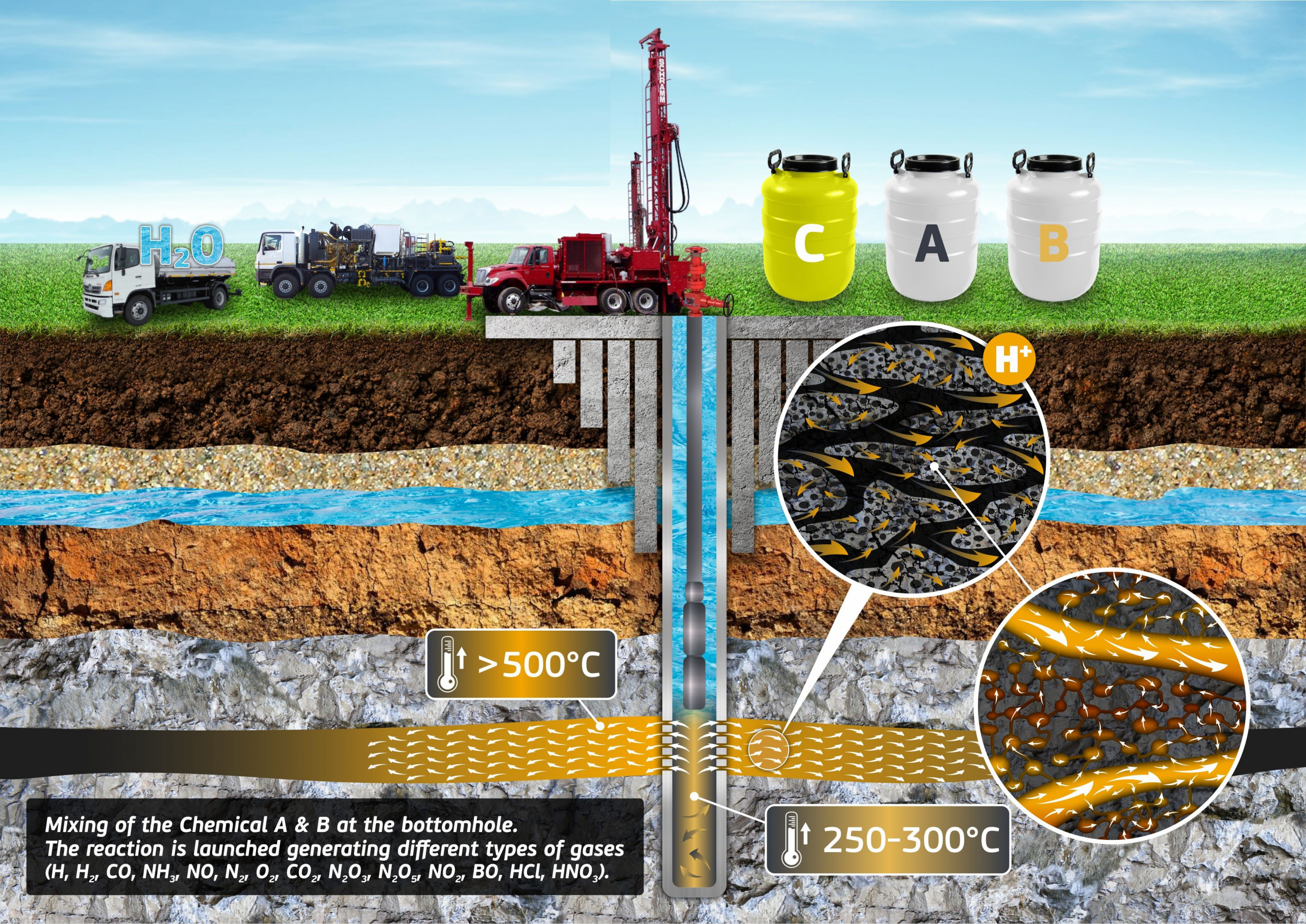

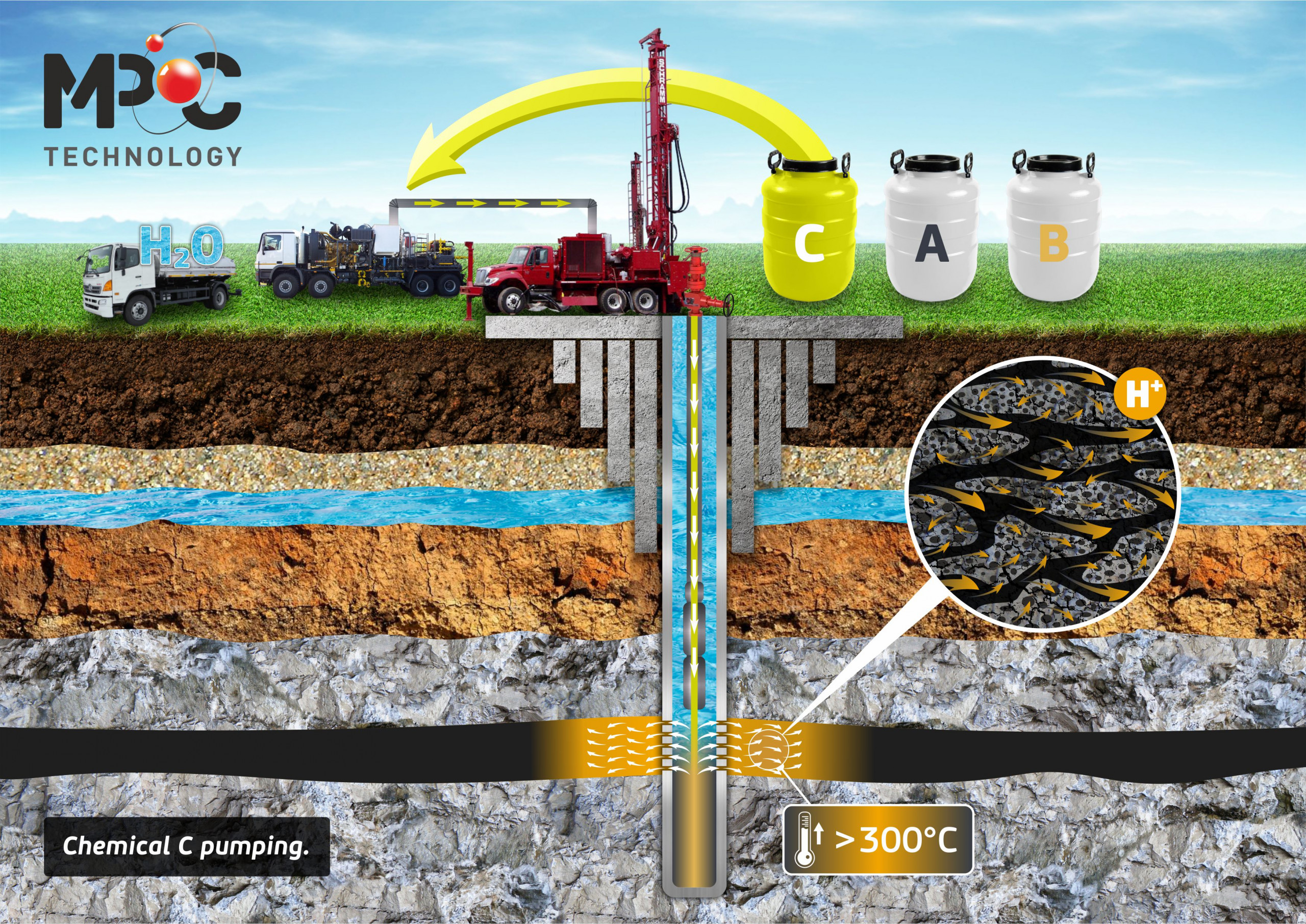

Our chemical complexes are to be delivered in the bottomhole zone of the well. They oxidize there under the action of the in-situ temperature, combustible components, and then burn in the water without access of air, releasing reactive gases and heat, simultaneously decomposing other components, for example, complex compounds of nitrates. Atomic and molecular hydrogen, oxides of nitrogen and carbon, vapors of nitric and hydrochloric acids are being evolved during a reaction. They effect multi-functionally on the formation and the fluid. The main working medium of the process is hydrogen, which has not only an extremely high penetrating power into the reservoir, but also increases the permeability for other gases.

A mixture of gases (hydrogen, oxides of nitrogen and carbon, acids and vapours, etc.) affects the formation. In contrast to the existing analogues this process breaks the chemical bond of hydrocarbons with rock fracturing, i.e., increases the completeness of extraction of oil and gas. Gases create pressure pulses, and discrete-impulse supply of energy many times greater than any mechanical impact. New fracks appear and spread out the existing ones in the rock. Uneven heating of gas particles expands unevenly with uneven They change position, “fixing” the cracks, preventing their “collapse”, when in situ pressure drops. Besides, gases condense in the cracks and pores forming the hot acid to dissolve the rock surface, which also contributes to increase in its permeability.

Changes are experienced both by the rock (its permeability increases) and the fluid that saturates it.

It is proved that the unique properties of new chemical energy sources are able to provide in-situ processing only of high molecular weight components of the fluid selectively If the molecules are longer, it easier to destroy them (their activation energy is less) to gasoline and gas fractions.

In-situ hydrogen cracking takes place primarily of heavy hydrocarbons. As a result, the permeability of the reservoir increases sharply and, consequently, improves the performance of oil, gas and gas condensate wells by:

- additional fracturing;

- opening of the closed pore space;

- In-situ hydro-cracking of high molecular hydrocarbons and transforming them into gasoline fraction;

- short-term in-situ combustion of resinous deposits;

- removal of skin-effect;

- a new kind of acid-alkaline treatment by heating the formation and strengthening of unstable collectors at the expense of secondary changes in the structure of the rock.